Sections

Text Area

(More information for DMP Flex 100 3D Metal Printer)

DMF Flex 100 can benefit the university community in the aspects of:

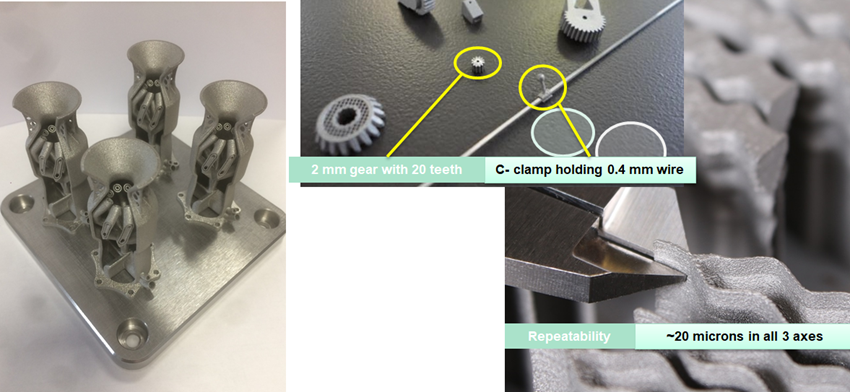

- Near-net-shape part with complex structure, which is difficult to be manufactured by traditional machining methods, can be realized by 3d metal printing in a lower cost and less time manner.

- 3D metal printed parts are fully dense, incorporating complex geometries and precise internal features that cannot be made with traditional machining alone.

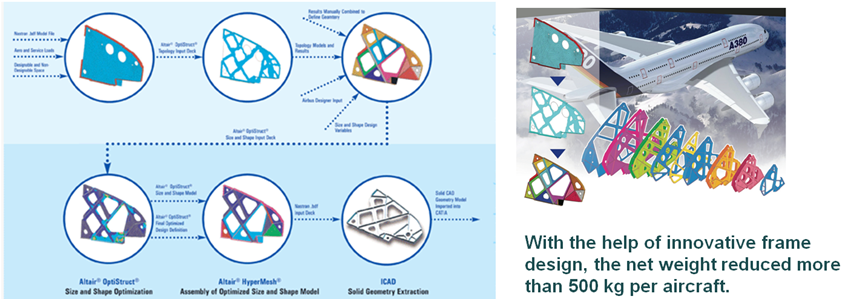

- Conformal cooling channels can be produced by 3d metal printing, and it can greatly improve performance and resistance to thermal stress. This is ideal for aerospace and automotive applications.

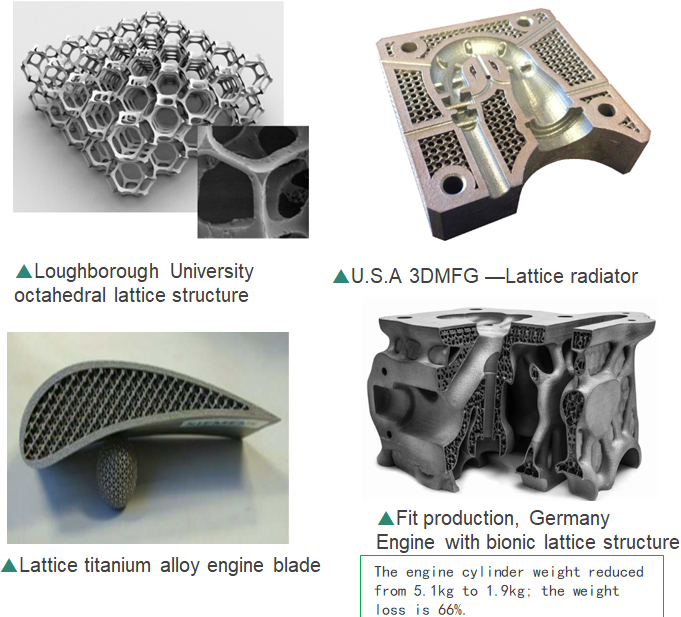

- Organic light-weight form can be produced by using lattice structure which is optimized topologically.

- Metal 3d printed parts have excellent physical properties and the available material range includes difficult to process otherwise materials, such as Cobalt Chrome alloy.

There are a number of metals can be used in the printing process by DMP Flex 100, including:

- LaserForm 316L (B)

- LaserForm 17-4PH (B)

- LaserForm CoCr (B)

The CoCrMo Alloy is a Ni-free alloy which is suitable for biomedical applications. Stainless steel 316L and steel 17-4PH are the mostly used materials in the fabrications needs of the university.

(Design guide for DMP Flex 100 3D Metal Printer)

Left Column

Image

Image

Right Column

Image

Image

Text Area

Technical Specification

| Layer Thickness (Z-axis) | 10-micron to 100-micron |

| Net Build Size (X×Y×Z) | 100 x 100 x 80 mm (3.94 x 3.94 x 3.15 inch) |

| Typical Accuracy | ±0.1-0.2% with ±50-micron minimum |

| Repeatability | X = 20-micron, y = 20-micron, z = 20-micron |

| Minimum Feature Size | X = 100-micron, y = 100-micron, z = 20-micron |

| Supported Materials | LaserForm 316L (B), LaserForm 17-4PH (B), LaserForm CoCr (B) |

| Input Data File Format | Native CAD formats and neutral CAD formats, e.g. IGES, STEP, STL |

| Software | 3DXpertTM all-in-one software solution for metal additive manufacturing |

Image

Image

Image Caption

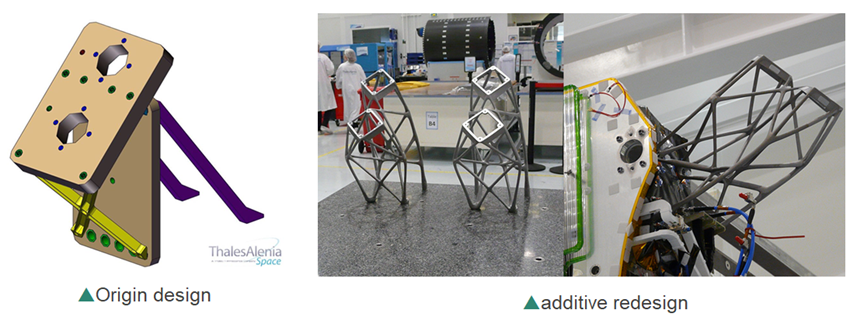

Additive redesign of Satellite antenna bracket - Parts weight loss 22%; Cost saving 30%;Shorten the production cycle in 2 months

Image

Image

Image Caption

Innovative design of airbus A380 front wing ribs

Image

Image

Image Caption

Redesign of topological lattice structure