Background

It is a Industrial Technology Funding (ITF) project. The feather sorter is used in shuttlecock manufacturing industry.

Objective

The degree of bending curvature of a feather will determines the performance of a shuttlecock that is from it. The system is capable of sorting the curvature of a feather into a maximum of 91 grading for shuttled production. The accuracy of grading is much higher that of manual selection.

Technology

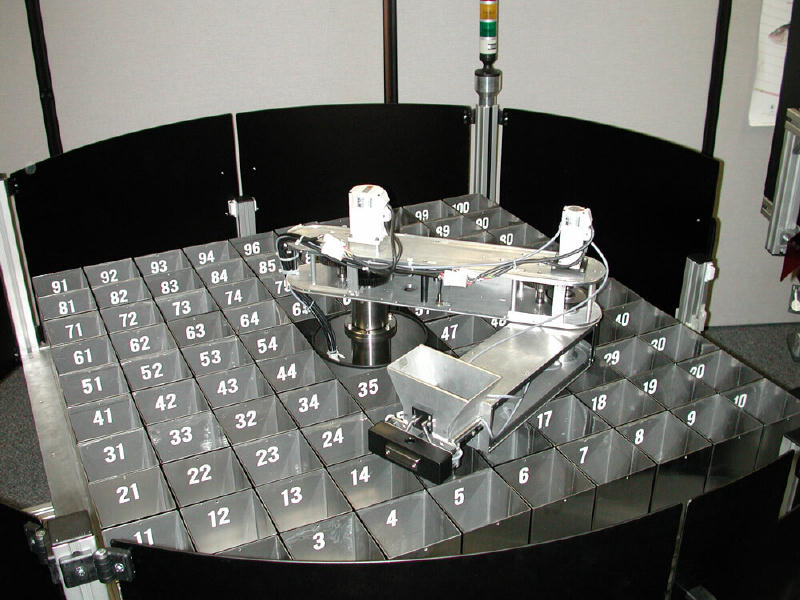

The system consists of two units. The first unit is a turning table with 18 sets of loading gripper for the loading of feathers and image capture. The second unit is a sorter with robotic arm which drops feather into the bin matrix according to the degree of curvature. The cycle time is 5 seconds and the maximum throughput of the system is 720pc/min.

CATIA has been used in the engineering design stage. It helps to minimizing any possible fault or error due to incompatible dimensional designation. 3D perspective views which generated in CATIA before proceeding to the component fabrication.

The prototype is completed and had been set up in a production line in Southern China.

Click to see the video clip of the sorting