Background

It is an Industrial Technology Funding (ITF) project. The deliverable of this project is an automatic robot cutter which is capable to cut the lateral connection branch opening during the repairing of underground drainage pipe of diameter from 900 to 1300mm.

Objective

This project aims to develop an automatic robot cutter that can cut the lateral connection branch opening during underground drainage pipe repairing in Hong Kong. The developed robot cutter will be able to work for underground drainage pipes of diameter from 900 to 1300mm, which now cannot be handled by commercially available robot cutter. Unmanned operation can also assure a safe workplace for the industrial practitioners.

Technology

A methodology with vision-based system to aid the operator to record the lateral opening information is needed. The methodology is reviewed and derived to cope with the used lining materials. The developed robot cutter will allow the industrial practitioners to perform the cutting of the opening at an automatic way. This could help to eliminate the need of sending an operator into the underground drainage pipe that will put the human in a highly risky environment.

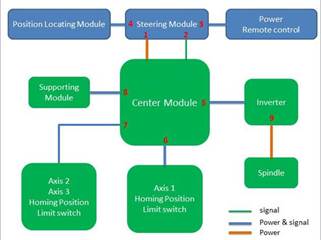

An appropriate cutting technology is selected and tested to be technically feasible for achieving the required cutting task. The operation procedure and algorithm for lateral opening data capture and cutting is then developed. An application specific main control board is designed to handle the power and communication between the vision module, cutting module, detection module, supporting module and steering module.